If you compare the heel (where the two legs of the angle meet on the inside diameter) of a rolled angle ring to the heel of a pressed ring you will see differences. The difference is, on a rolled angle ring, the heel is a true ninety degrees. On a stamped angle ring, you will find a radius that is at least the thickness of the material, often times more.

The Competitor’s Stamped Rings Back To Back

Midwest’s Rolled Rings Back To Back

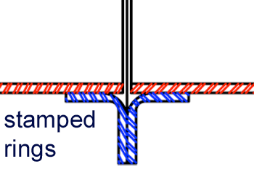

If you put a rolled ring on to a piece of pipe, the pipe will fit nicely to the heel of the rolled ring. On a stamped ring, there is a gap between the heel and the wall of the pipe. That gap can cause a variety of problems. There are a number of very large companies including INTEL, SAMSUNG, TEXAS INSTRUMENTS, KIMBERLY CLARK, MOTOROLA, who have done research and have proved that this is a point where air leakage can start. It causes a turbulence in the air flow and it also causes less surface area to be in contact with the mating ring.

Avoiding Air Leackage and Germ Harbors

Aside from air leakage, this area can also become a germ and dirt harbor. If you look at the cross section of two stamped angle rings back to back, there is V shaped groove. If you are collecting dust or any particulate matter, this is an area where that dust can get trapped and then over time, it will start to have a snow ball effect where the dust starts to accumulate. Before you know it, you’ll have a serious restriction in your system.

Aside from the V groove, there can also be a gap between the duct wall and the heel of the ring. Often time duct fabricators will “dress” the duct by hitting it with a hammer or tool so the duct wall is touching the heel or a portion of the heel of the stamped ring. This takes time, money and energy and with a rolled ring is a step that doesn’t need to be taken.

Aside from the V groove, there can also be a gap between the duct wall and the heel of the ring. Often time duct fabricators will “dress” the duct by hitting it with a hammer or tool so the duct wall is touching the heel or a portion of the heel of the stamped ring. This takes time, money and energy and with a rolled ring is a step that doesn’t need to be taken.

Vanstoning is when a fabricator will bend an edge of the duct work to a ninety degree form once the angle ring has been slipped over the pipe. Often times, the angle ring is used as the hard edge to bend a piece of pipe or duct to vanstone it. It is much easier to vanstone a piece of ductwork on a true ninety degree heel than it is on a heel with a radius. Think of using a press brake that would have a rounded edge; it would hardly work! This is the same idea as vanstoning over a pressed or stamped angle ring. Lastly when you vanstone on a stamped ring, you are using approximately 1/2″ more of duct to make up for the radius of the heel.

In extremely tough environments, rolled angle rings handle abuse better than stamped rings. We have one customer who converted to our rolled rings specifically for this reason. When you stamp sheet metal and draw the collar, you are making millions of microscopic tears in the metal. These small tears can be points where a ring can start to break over time, especially if there is vibration present in the system or application.

Midwest Metal Products stamps, 3″, 4″ and 5″ angle rings. Because a number of very large businesses specify rolled rings, we can also roll 4″ and 5″ rings.

Here is a stamped angle ring on a piece of blowpipe. You can see the germ harbor which is created by the radius of the stamped ring’s heel. Often times, fabricators dress the duct to the heel to try to eliminate this gap, a costly and time consuming process.